India and China aren’t just making cheap pills-they’re running the world’s medicine supply chain

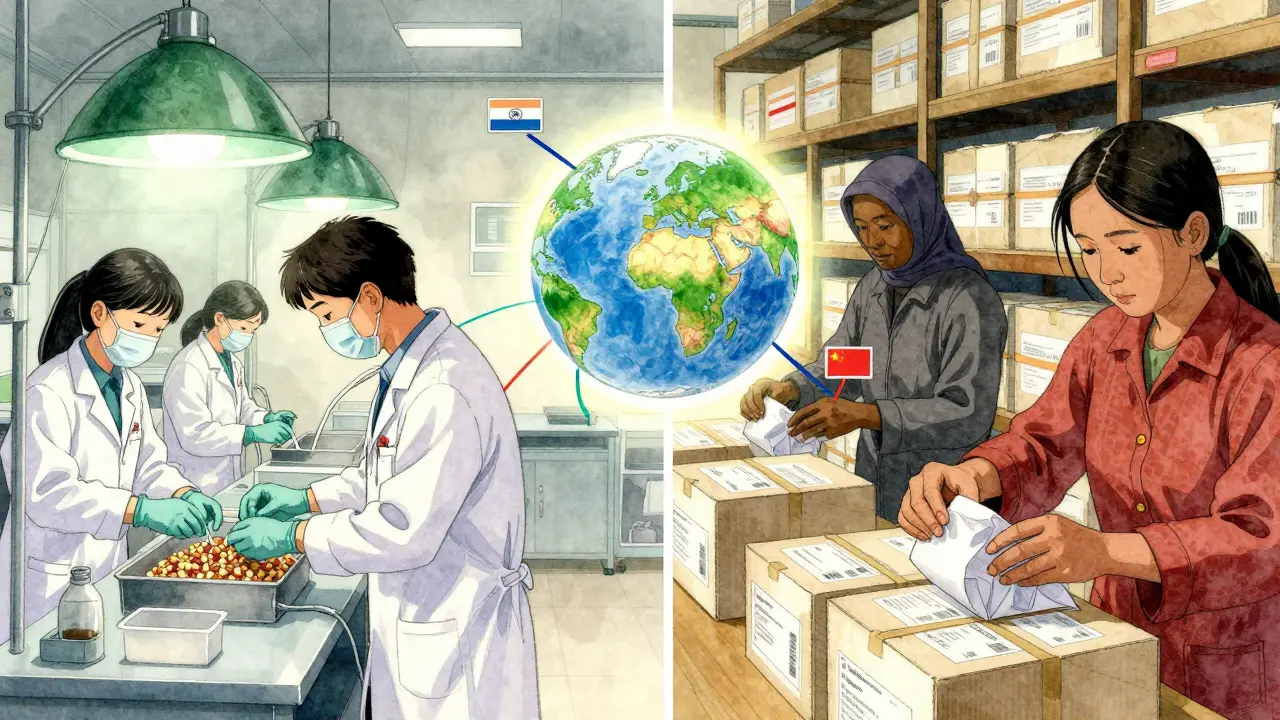

If you take a generic blood pressure pill, an antibiotic, or a vaccine, there’s a very good chance it came from Asia. India and China together produce more than half of the world’s generic medicines and nearly 70% of the raw ingredients that go into them. But they don’t do it the same way. India is the volume king-churning out billions of tablets at low cost. China is the value king-controlling the supply of active ingredients and moving fast into complex biologics. Meanwhile, countries like Vietnam and Cambodia are slipping into niche roles that bigger players ignore.

It’s not just about price anymore. Regulators in the U.S. and Europe are watching closer than ever. A single FDA warning letter can shut down a factory for months. Supply chains are being rebuilt-not because of politics, but because of risk. Companies now source from both India and China at the same time. And that’s changing everything.

India: The pharmacy of the world, built on policy and volume

India’s rise wasn’t luck. It was a deliberate policy move in the 1970s. The government changed patent laws to allow companies to copy drug formulas as long as they used a different manufacturing process. That opened the floodgates. By 2024, India’s pharmaceutical market hit $61.36 billion, with 75% of that coming from generic drugs. The country now supplies over 60% of the world’s vaccines and 40% of all generic drugs sold in the U.S.

Most of this production comes from just two states: Gujarat and Maharashtra. Together, they handle over 60% of India’s drug manufacturing. There are more than 3,000 facilities approved by the U.S. FDA-more than any other country. But here’s the catch: only 15% of those factories can make biologics. That’s the new frontier-expensive, complex medicines made from living cells. India is trying to catch up, but it’s behind.

India’s biggest weakness? It still imports 68% of its Active Pharmaceutical Ingredients (APIs) from China. That’s a huge vulnerability. Even though the government launched “Pharma Vision 2020” and now “Pharma 2047” to fix this, domestic API production only meets 18% of demand. Twelve new API parks are under construction, but it will take years to replace what’s imported.

What India does well: speed, flexibility, and communication. If you need a custom formulation, Indian manufacturers can deliver in 14 days. Chinese suppliers? At least 30. U.S. pharmacy chains report a 60% drop in customer service issues when working with Indian firms. That’s why even with quality concerns, many buyers still prefer India.

China: The hidden engine behind every pill

China doesn’t just make drugs-it makes the stuff that makes drugs. It controls 70% of the global supply of Active Pharmaceutical Ingredients. That means if you’re making aspirin, metformin, or amoxicillin anywhere in the world, chances are the core chemical came from China. In 2024, China’s pharmaceutical market hit $80.4 billion, bigger than India’s, but its growth is slower: just 5.4% per year since 2018.

China’s advantage isn’t volume-it’s scale and vertical control. It doesn’t just produce APIs. It mines the raw materials, refines them, and turns them into finished drugs. Its manufacturing hubs in Jiangsu, Zhejiang, and Shanghai are built for efficiency. And unlike India, China has poured billions into biologics. Between 2020 and 2024, 45% of new pharma facilities were built for biologics production.

But quality has been a problem. In 2024, the FDA issued 142 warning letters to Chinese manufacturers-more than double the number for Indian firms. Many of those letters cited data manipulation, poor sanitation, or unapproved changes in production. That’s why big buyers now use dual sourcing: 68% of U.S. pharmacy chains now get generics from both India and China to avoid being stuck if one side fails.

China’s approval process is faster now-12 to 18 months compared to India’s 18 to 24. But here’s the catch: foreign companies must own at least 51% of their distribution business in China. That’s a high barrier. Still, the cost to set up manufacturing is lower: $200,000 to $350,000 versus India’s $350,000 to $500,000.

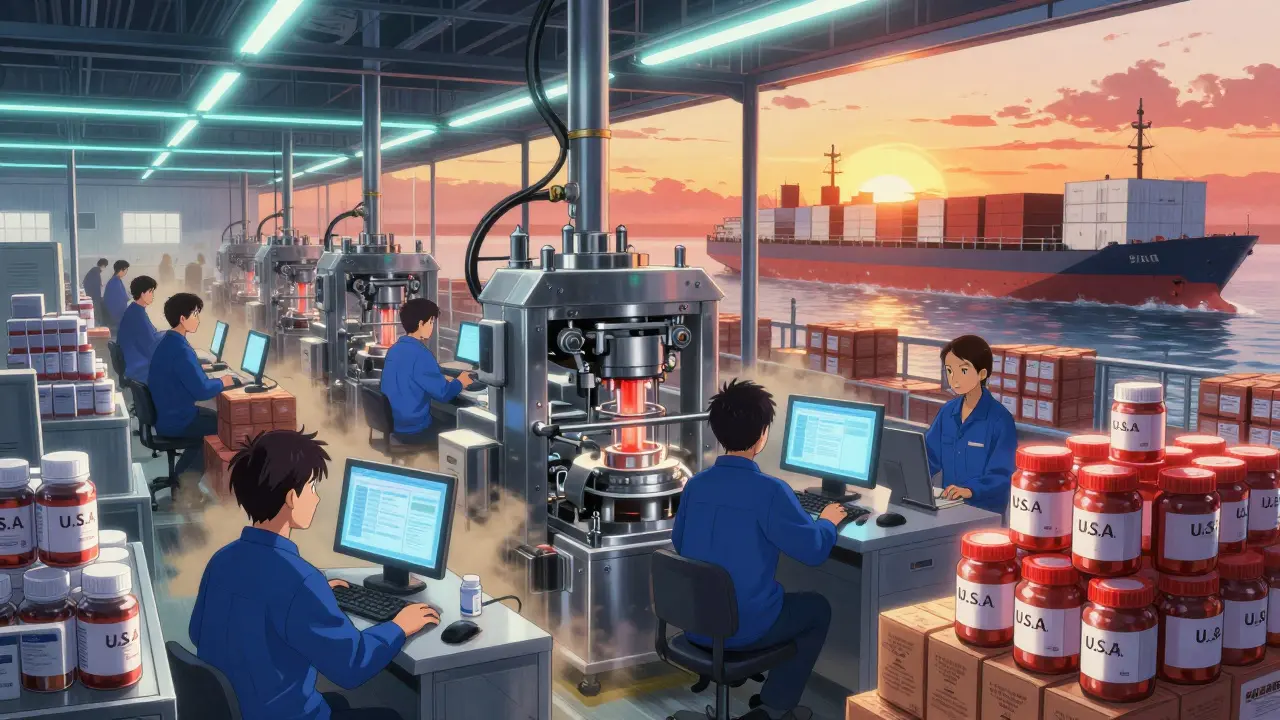

Why the U.S. and Europe are doubling down on both countries

For years, buyers chose between India and China based on price. Now, they’re choosing both. The reason? Risk.

One factory shutdown in China can delay a life-saving antibiotic. One regulatory delay in India can hold up a cancer drug shipment. So companies are spreading their bets. A typical U.S. pharmacy chain now gets 40-60% of its generics from India and 25-35% from China. That way, if one source has problems, the other can fill in.

It’s not just about medicine. It’s about trust. Indian suppliers score higher on communication-4.3 out of 5 on Trustpilot versus China’s 3.7. But Chinese suppliers win on price-4.5 versus 4.0. So buyers are learning to live with the trade-offs. One German healthcare company said after the 2024 FDA warnings, they had to spend 18% more on supply chain costs just to add Indian backup suppliers.

And now, the U.S. is pushing for traceability. Under “Project BioSecure,” every API must be tracked from raw material to finished pill. That’s expensive. It could add 18-22% to compliance costs for Asian manufacturers. But it’s coming. And companies that can’t adapt will lose contracts.

Emerging players: Vietnam, Cambodia, and the new niche game

India and China aren’t the only ones playing. Smaller countries are carving out their own space.

Vietnam’s pharmaceutical market grew 12.3% per year from 2020 to 2024. Why? Antibiotics. Vietnam now produces high-purity antibiotic intermediates that Indian and Chinese firms buy to finish into pills. It’s not flashy, but it’s profitable. In 2024, Vietnam exported $2.8 billion in pharma products-a 24.7% jump from the year before.

Cambodia? It’s not making drugs. It’s making the boxes and devices that hold them. Medical device assembly is growing at 18% a year. Thanks to ASEAN trade deals, Cambodia gets preferential access to U.S. and EU markets. It’s low-tech, but it’s stable. And it doesn’t require the same level of regulatory scrutiny as drug manufacturing.

These countries aren’t trying to beat India or China. They’re learning how to work with them. Vietnam supplies intermediates to Indian API makers. Cambodia assembles packaging for Chinese drug exporters. It’s a new kind of supply chain-one built on specialization, not scale.

The future: Innovation, self-sufficiency, and price wars

Both India and China are trying to move up the value chain. India wants to make biosimilars-copies of expensive biologic drugs-and is investing $13.4 billion to reduce API imports from 68% to 30% by 2030. China is spending $22.8 billion on biologics R&D under “Healthy China 2030,” aiming for 25% of exports to be high-value biologics by 2030.

But there’s a problem. Both countries are building too much capacity. S&P Global warns that overproduction could trigger a 15-20% drop in API prices between 2026 and 2027. That means profits will shrink. Companies that can’t innovate or cut costs will get squeezed.

India’s biggest edge? Its population. Two-thirds of its people are under 35. That means a growing domestic market for medicines-and a huge pool of young engineers and scientists. If India can turn that into innovation, it could close the gap with China by 2035.

China’s edge? Money and central planning. It doesn’t wait for market signals. It directs billions into R&D and infrastructure. That’s why its pharmaceutical stock index rose 14% last year-while India’s rose just 5%.

The real winner? Buyers. With more suppliers, better quality control, and more competition, generic drug prices will keep falling. But only if regulators keep pushing for transparency. And if companies keep diversifying their sources.

What this means for you

If you’re a patient: you’re getting cheaper, reliable medicines because of this system. A month’s supply of generic metformin in the U.S. costs under $5 because of India and China.

If you’re a buyer: don’t rely on one country. Build dual sourcing. Test batches. Track your suppliers. Quality isn’t guaranteed anymore-it’s earned.

If you’re an investor: India offers growth in volume and consumer demand. China offers growth in technology and value. Both are risky. Both are essential.

The global generic market is worth $448.6 billion. Asia makes 38.7% of the volume-but only 24.3% of the value. That gap is shrinking. And the next five years will decide who controls the future of medicine.

Comments

Oladeji Omobolaji

Honestly, I never thought about where my blood pressure pills come from. Now I'm just glad they're cheap and work. India and China might not be perfect, but they keep people alive.

Also, Vietnam making antibiotic intermediates? That's wild. Small players doing big things.

On January 22, 2026 AT 21:13

Janet King

The data presented here is accurate and well sourced. Regulatory oversight remains critical. Dual sourcing is not a trend it is a necessity. Supply chain resilience must be prioritized over cost savings alone.

On January 23, 2026 AT 20:21

Andrew Smirnykh

It's fascinating how two very different systems both ended up dominating the same industry. India's agility versus China's scale. Neither is better outright. They just serve different needs. And honestly? The fact that Vietnam and Cambodia are finding their niche instead of trying to compete head on? That's smart economics.

On January 25, 2026 AT 02:21

Kerry Evans

This whole thing is a disaster waiting to happen. We outsource the most critical part of our healthcare to countries with terrible track records on data integrity and sanitation. And now we're surprised when things go wrong? We knew this was risky. We chose to ignore it. That's not globalization. That's negligence.

On January 26, 2026 AT 13:17

Susannah Green

I work in pharma logistics, and this is spot on. Indian companies reply to emails within hours. Chinese ones? Sometimes weeks. But if you need 10 million tablets yesterday? China can deliver. India? You get it in three days with a friendly call from the plant manager. Both are essential. Just know what you're getting.

On January 28, 2026 AT 00:10

Anna Pryde-Smith

This is why your insulin costs $300. This is why your child's antibiotic was delayed for a month. This is why we're all just one geopolitical tantrum away from a public health crisis. And we're all just sitting here like it's normal. It's not normal. It's terrifying.

On January 28, 2026 AT 06:36

Vanessa Barber

Wait, so the whole world depends on two countries that hate each other to keep us alive? And you're telling me this is stable? I'm not buying it. This is a house of cards made of APIs.

On January 29, 2026 AT 18:13

dana torgersen

i think... like... the real issue isn't india or china... it's that we've forgotten how to make stuff ourselves. we outsourced everything and now we're just... hoping for the best? like, isn't that kinda... dumb? also, i think 'biologics' is spelled with two l's? maybe? idk

On January 30, 2026 AT 12:25

Dawson Taylor

Diversification is not optional. It is structural. The market has spoken. Reliance on single-source supply chains is a relic of the 20th century.

On January 30, 2026 AT 23:43

Sallie Jane Barnes

I'm so proud of how smaller countries like Vietnam and Cambodia are stepping up. They're not trying to be giants. They're just being smart, finding their place, and building something real. That’s the kind of innovation we need more of.

On February 1, 2026 AT 03:06

Laura Rice

OMG I JUST REALIZED-my grandma’s diabetes meds? Probably made in Gujarat. And the box they came in? Made in Cambodia. That’s wild. Like, the whole world is connected in ways we never think about. And we just take it for granted. We should be thanking people we’ll never meet.

On February 2, 2026 AT 02:11

charley lopez

The API supply chain exhibits significant vertical integration in China, whereas India demonstrates horizontal scalability in formulation. The regulatory divergence in FDA compliance metrics reflects structural differences in governance and quality assurance protocols.

On February 2, 2026 AT 02:51

Kerry Moore

I appreciate how this breaks down the real trade-offs instead of just blaming one country. The fact that buyers are using both India and China isn't weakness-it's strategy. And the traceability push? Long overdue. We need to invest in transparency, not just cheaper pills.

On February 3, 2026 AT 18:11

Sue Stone

I just bought a month's supply of metformin for $3.79. This whole system? Works.

On February 4, 2026 AT 11:30